Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Ask any scientist who has worked with cell cultures in the lab: contamination is high on their list of fears. Even one stray bacterial or fungal spore can ruin the entire experiment.

Now imagine increasing that risk biomanufacturingwhich uses living cells to make a variety of products, including medicine, food, and industry. There, contamination not only hinders productivity, it can harm people if, for example, harmful germs get into medicine.

Not wanting to take any chances, companies take a counter-destructive approach, blasting their equipment with hot steam. But it is an expensive method: the steam takes a lot of energy to produce, and the equipment must be hardened against the high temperatures and pressures that occur during the steaming process.

“This was a process developed by Pfizer in the 40s to make penicillin,” said Brian Heligman, founder and CEO of Biospherehe told TechCrunch. “And you look at the early systems, they look the same as today.”

Steam isn’t the only way to reduce hardware costs. Another is to grow cells in single-use batteries, which is wasteful. Ultraviolet (UV) light is another. However until recently, producing enough UV-C light, which is needed for removal, has been expensive. Now, thanks in part to COVID, it’s much cheaper.

“In the Covid era, you saw a lot of investment in UV-C LEDs,” Heligman said. “They’ll probably get orders for less in the next decade.”

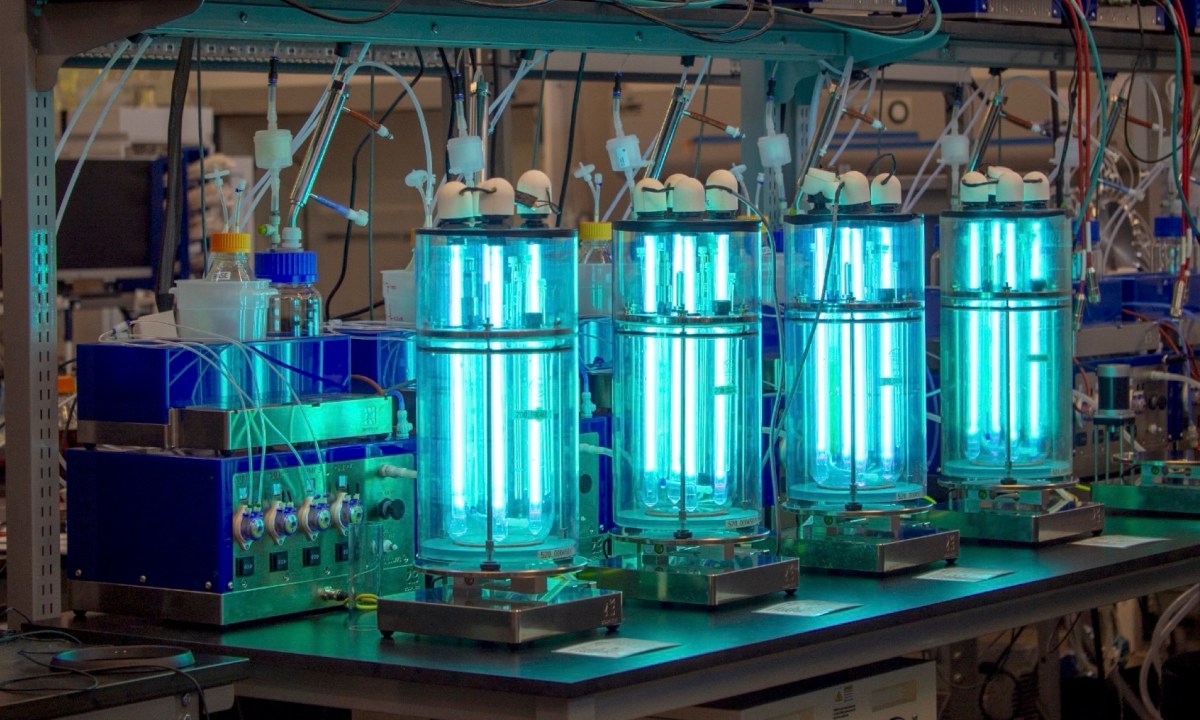

Heligman and his colleagues at Biosphere have spent the past two years developing a three-liter glass reactor that can be sealed with UV light. Inside the reactor, four bright LEDs flash across the chamber and its components. The startup is now testing eight of them as part of a $1.5 million Department of Defense grant project exploring ways to use biomanufacturing to produce high-quality oil.

The use of LEDs can lower the cost of biomanufacturing, allowing such processes to produce devices that would previously have been prohibitively expensive.

“The easier it is to disrupt these systems, the more we think we can push them down,” Heligman said.

“You can think of this as an electric bioreactor,” he said, adding that replacing expensive stainless steel valves, traps, and other equipment with LEDs and cable should help drive costs down significantly. In addition, because the vessels will not need to withstand high temperatures and pressures, they can be made of cheaper materials such as plastics.

The company is currently working on building a pilot system that can hold about 100 liters and can be sealed using its technology. After that, Heligman said he is interested in researching designs that can hold 40,000 to 80,000 gallons.

Biosphere has raised $8.8 million in seed funding led by Lowercarbon Capital and VXI Capital, the company told TechCrunch. Participating investors include B37 Ventures, Caffeinated Capital, Founders Fund, and GS Futures.