Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

As someone who has painted walls in almost every home I’ve lived in as an adult, let me say that painting sucks. I’ve learned tricks over the years to get the job done quickly (I always have paint supplies!), but I still end up with a long, annoying process that takes more time than you’d expect.

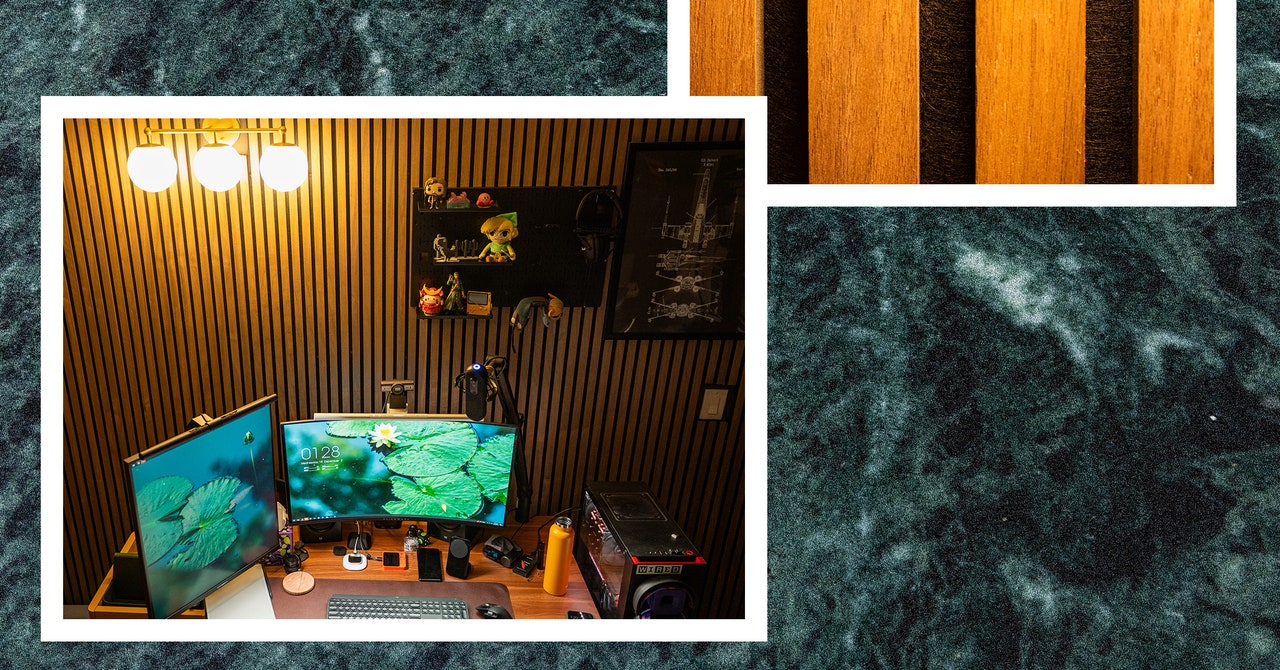

Last year I was lucky enough to become a homeowner, and naturally the Great Algorithm took notice and started pushing all kinds of home improvement projects, sales, and jobs on my Instagram. (Did you know you can get a roof replacement for free? Yes, it seems too good not to happen.) One caught my eye,Wood Veneer Hub. I saw an ad scrolling through my feed showing a home design with a beautiful wooden wall. It was exactly my aesthetic.

The company promises an easy installation – a room setup that won’t take a tiring day of painting, and it offers a lot. As WIRED’s resident home office tester, I decided to put these panels to the test my office. I have done it standing desks, office furniture, web camsdesk lamps, even storage cabinets, but I’ve never tried something that would really change the look of my space.

Wood Veneer Hub’s Slatpanels, as they’re called, consist of thin strips attached to re-examined materials with sound-absorbing properties. Each box contains two Slatpanels with nine slats per panel—you’ll need to measure your walls (or ceiling!) to find the size you need. You can choose between No Finish or Oiled Finish, and I recommend the latter – it costs more but saves you the trouble of applying a finish and protecting the wood.

I decided to try them on one of the walls in my home office, as an acoustic wall. It took about 13 Slatpanels (I was sent seven boxes, which means I was left with one Slatpanel), and I threw them into the metal. You can put it on top of your board, but I thought it looked better without my board, so I took it off. There is a small gap between the panels and my floor but it is not noticeable. This also means that I don’t have to cut the panels (except for outlets and light switches).

That’s the hard part – cutting the holes. I had to cut several holes for the outlet, the power switch, and my light fixture. If you have a chainsaw, you’re already in a better place than I am. I had a simple hand saw and no bench, so it was difficult to get straight lines and cut pieces. I used mine Milwaukee Fastback the knife to cut from the felt side first, and it did a surprisingly good job. Be smarter than me and use a long level or ruler and draw on the panels to keep the lines straight. Luckily, you have to look closely to see what my holes are like, or so I tell myself.